Global 5-axis competence

DMG MORI is installing centres of competence for 5-axis machining and 5-axis simultaneous machining all over the world and expects enormous customer potential

Milling with five axes, especially 5-axis simultaneous machining, is one of the most fascinating processes, albeit one of the most demanding ones. While 5-axis milling has become well established on a broad front in the past two decades in Germany and Europe, companies in other markets are still hanging back. Far too many, believes the world market leader DMG MORI, who has started a global competence campaign in the form of international 5-Axis Excellence Centres.

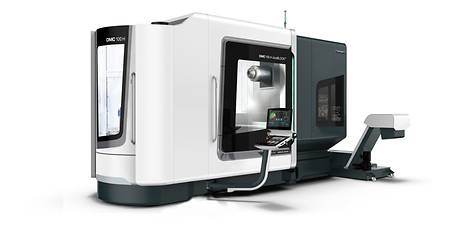

With a wide product portfolio and a high market presence, DMG MORI has long grown to become a leading supplier of machine tools with 5-axis technology. DECKEL MAHO Pfronten has been able to place more than 15,000 5-axis machining centres from the monoBLOCK and duoBLOCK series as well as from the field of portal machines on the market.

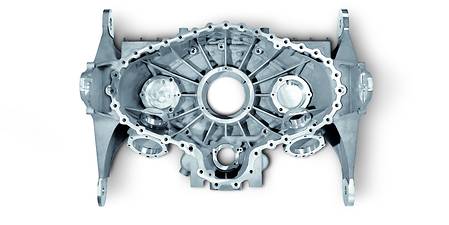

The reason for the strong focus on 5-axis solutions is the manufacturing advantages for the whole process. Alfred Geissler, Managing Director of DECKEL MAHO Pfronten GmbH, provides examples: “Tools can machine an area at the required angle, instead of milling it with 3 axes in numerous small steps. Or cross bores and undercuts – these cannot, in comparison, be produced economically at all on a three-axis machine. Even more fascinating is the geometrical flexibility, as can be seen in many customer applications. As 5-axis machining is usually complete machining in one setup, users benefit widely. The manufacturing of complex workpieces is more economical due to the minimal setup requirements and more precise than the sequential 3-axis machining, as there is no loss of accuracy during retooling.

Developing 5-axis technology jointly

DMG MORI as innovative leader has continuously improved its 5-axis machining centres and universal machines and adapted them to the growing demands of the market. The most recent example for this is the duoBLOCK, which is already provided by the machine tool manufacturer in its fourth generation. “We have succeeded in improving core features like precision, performance and efficiency by up to 30% percent compared to the previous generation”, says Alfred Geissler about further development. It goes without saying that this also applies to the DMC series. In addition to the mentioned properties, these models also have a fast pallet changer for short idle times.

In the field of components, DMG MORI now increasingly uses synergy effects from cooperation with Japanese developers. This is how the powerMASTER motor spindle was created, which impresses with 1,000 Nm torque, 77 kW of power in the duoBLOCK sector. The integrated spindle growth sensor (SGS) also compensates spindle growth and guarantees maximum precision. Furthermore, this speedMASTER spindle which was jointly developed as well will function as standard spindle for all DMU, DMU eVo and monoBLOCK machines in future. It ensures 30 percent higher chip removal rates compared to the current standard spindle and higher accuracy due to large spindle bearings. Added to this is an extended service life, which is reflected in the warranty period of 10,000 operating hours or 18 months respectively.

The broad range of 5-axis machines, but also the combination of 5-axis machining with milling/turning, ULTRASONIC or LASERTEC procedures as well as additional software offers – for example special technology cycles or the DMG MORI process chain – support DMG MORI in meeting almost all customer demands. 5-axis milling used to be more of a European affair at the start, as there was a trend towards more complex integral workpieces to reduce the number of components. Globalisation finally contributed to this trend also spreading internationally and 5-axis machining being increasingly accepted.

Customer proximity thanks to 5-axis Excellence Center

The growing interest in 5-axis solutions will be met by DMG MORI in future with the comprehensive product portfolio as well as the entire technical expertise in this field. “Simultaneous machining in particular places high demands also on the process chain from CAD via CAM through to control technology, and the competence of employees naturally is in construction, work preparation and the workshop”, says Alfred Geissler. For this reason, DMG MORI is also in demand as consultant. Spreading the word about the fascination of 5-axis milling around the world and holistically imparting all that this requires to our international customers is the task of the new 5-axis Centres of Excellence that we are establishing all over the world close to the customer.” The first one has already been opened last June in Padua in Italy. More 5-axis Centres of Excellence will initially be established in Japan, USA, China and Korea. The aim here is sensitisation of customers to the possibilities, but also the challenges of 5-axis machining, as Alfred Geissler adds: “We will offer seminars and training courses to achieve this. In addition, customers will have the opportunity to carry out individual application tests together with our specialists on site, in order to gain experience and therefore put their investments on a good footing.”