Discover the Anatomy of a Machine Tool

Highest production standards and extensive inspections ensure maximum quality at the DMG MORI manufacturing facility in Davis

DMG MORI’s North American manufacturing facility, located in Davis, California, was opened in July 2012. DMG MORI is dedicated to offering customers comprehensive local service and support for the highest quality of U.S. made machine tools. At IMTS, visitors will experience live demonstrations on locally manufactured machines and take a virtual tour through the factory in Davis. They will discover how DMG MORI builds its machines seamlessly from design to production. They will learn about the anatomy of a machine tool and what is under the covers.

The DMG MORI facility in Davis manufactures and assembles different models of NHX horizontal machining centers as well as the DMU 50 five-axis universal milling machine.

With a production capacity of up to 100 machines per month on a production area of 221,000 ft2, the Davis location manufactures and assembles the 40-taper NHX 4000 2nd Generation, the 50-taper HX 5000 2nd Generation, the 50-taper NHX 6300, and the DMU 50 five-axis universal milling machine. The design and production activities by more than 150 employees in California offer DMG MORI’s North American customers not only the world’s best CNC hardware, but provide price-competitive, customized technical solutions to today’s most demanding production problems.

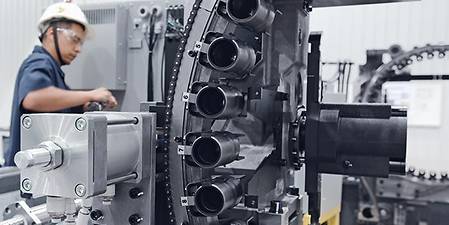

DMG MORI employs a sophisticated 6,700 ft2 automation center for unattended, in-house machining of the most critical components for the machines produced at the North American manufacturing facility. The machining system includes four machining cells, eight CNC machines, more than 100 machine pallets and seven robots to complete the washing, cleaning and material handling. DMG MORI’s cell control software (LPS) manages all of the machining programs, production schedules and provides all necessary control of production; monitoring and reporting of machine status is performed by DMG MORI’s Messenger software.

State-of-the-art technologies, high-tech components and optimized logistic processes ensure perfect conditions to produce 100 machines per month on a production area of 221,000 ft2.

With a 100 percent component inspection of all critical components during the assembly process including accuracy, coolant leaks and function tests the machine tool manufacturer ensures that the product meets the highest standards. Each product also completes 100 hours of running tests in order to make certain the machine is ready for any type of production environment.